Freeform Future Corp. has successfully secured $67 million in funding to advance its innovative 3D metal printing technology. This latest investment round included prominent participants such as Nvidia Corp.’s NVentures and Boeing Co.’s AE Ventures, both of which previously supported Freeform during its Series A fundraising in 2024. Additional backing came from Apandion, Founders Fund, Linse Capital, Threshold Ventures, and Two Sigma Ventures.

In traditional manufacturing, metal components are typically produced using CNC machines, which are known for their complexity and lengthy setup times. This inefficiency can render them impractical for low-volume production tasks, where the investment in setup may outweigh the benefits. Freeform aims to solve this issue with its advanced metal 3D printing technology, allowing for quicker reconfiguration between parts—resulting in lower production costs and minimized metal waste.

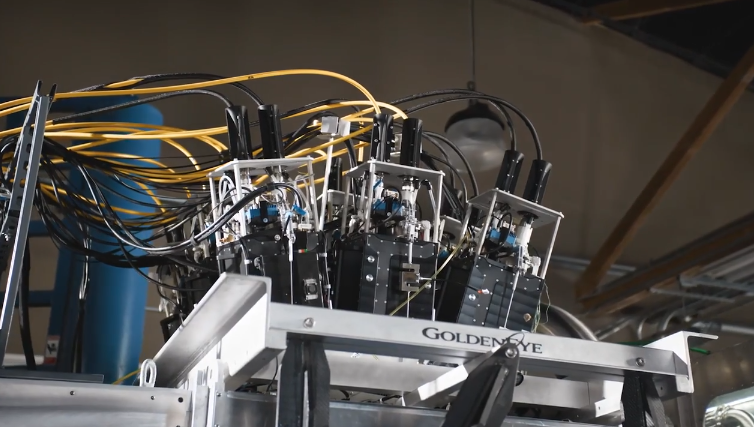

The centerpiece of Freeform’s technology is its GoldenEye 3D printing system, optimized for metal fabrication. Utilizing 18 lasers, this system processes metal powder while integrated sensors monitor the manufacturing workflow, enhancing efficiency.

The commonly utilized 3D printing method, known as Selective Laser Melting (SLM), involves layering thin sheets of metal powder, which are fused together by powerful laser beams. This technique is often powered by specialized fiber-optic cables containing ytterbium, a rare-earth element crucial for quantum computing applications.

Quality control is vital in the 3D metal printing process, as insufficient heating of metal powder can lead to poor fusion and structural weaknesses, resulting in defects. Freeform operates a dedicated facility focused on producing parts for clients rather than selling printers, effectively eliminating the need for clients to establish their own production lines and associated technical staff.

Proceeds from the recent funding will enable Freeform to enhance its GoldenEye system. The company is set to unveil a new model named Skyfall, which will feature hundreds of lasers and is expected to produce “thousands of kilograms of metal parts” daily. This machine is projected to increase manufacturing capacity more than 25 times. Moreover, Freeform plans to bolster its workforce by hiring up to 100 new employees to support its ambitious growth objectives.