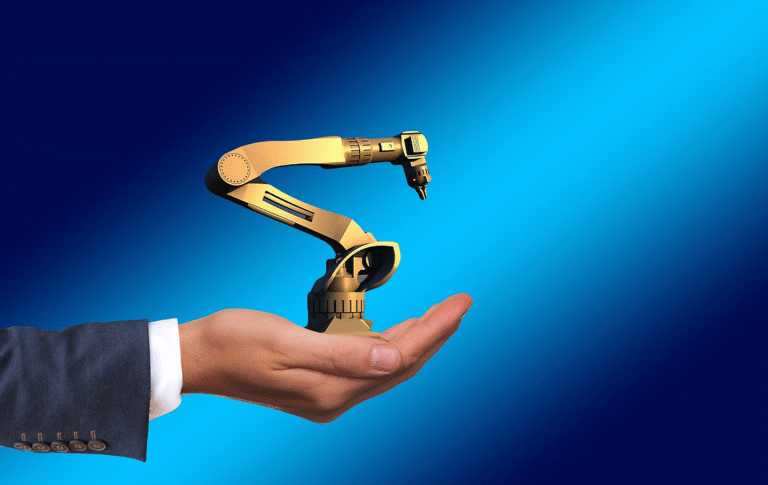

Supply chain robotics and automation leader Mytra Inc. has announced a significant milestone in its growth trajectory, successfully securing $120 million in funding to enhance warehousing efficiency. This capital infusion is earmarked to accelerate the deployment of its pioneering automated storage and retrieval systems, which merge advanced robotics with AI-driven software to transform warehouse operations.

Mytra’s innovative approach addresses the pressing need for automation within the logistics and warehousing sectors, which have seen minimal evolution in their operational methodologies over the past century. With approximately half of manufacturing labor in the U.S. dedicated to material handling, as stated by the U.S. Census Bureau, the demand for modernization is clear. However, conventional warehouses still rely heavily on human labor, contributing to the over 400,000 unfilled positions in the industry—a figure projected to surpass 2 million by 2030 according to the National Association of Manufacturers.

To tackle these challenges, Mytra has created a highly automated and space-efficient storage system characterized by three core components: customizable robots, modular storage racks, and an AI-powered operating system. This modular matrix utilizes versatile steel cubes, allowing for the construction of a high-density storage grid that optimizes vertical and horizontal space, eliminating the need for fixed aisles. The MytraBots, described as low-profile robots, navigate in multiple dimensions within this grid, efficiently lifting storage trays containing various goods.

The advanced warehouse execution system at the heart of Mytra’s operations seamlessly controls the MytraBots, ensuring optimized routing and reduced friction in their movement. This technology allows for dynamic reconfiguration of storage matrices, adapting to specific inventory needs and enhancing throughput while significantly minimizing the need for manual labor, thereby improving workplace safety.

Co-founder and CEO Chris Walti emphasized the transformative potential of their platform, asserting that Mytra is not merely enhancing existing systems but fundamentally reconstructing the infrastructure essential for modern industrial processes. “Material flow should operate like cloud computing: abstracted, programmable, and continuously optimizing,” Walti stated.

Mytra’s innovative solutions have attracted interest from Fortune 500 companies and will continue to drive demand, as evidenced by a recent contract to develop a storage matrix 60 times larger than their prior largest model. The Series C funding round was led by Avenir Growth, with participation from both new and returning investors, signaling strong confidence in Mytra’s vision and market potential.

This new investment will enable rapid expansion of Mytra’s deployment capabilities and further bolster its workforce, setting the stage for significant advancements in warehouse automation.